Classification of stud welding

Classification of stud welding:

Stud welding can be divided into two categories: "stored energy stud welding" and "arc stud welding".

What is stored energy stud welding?

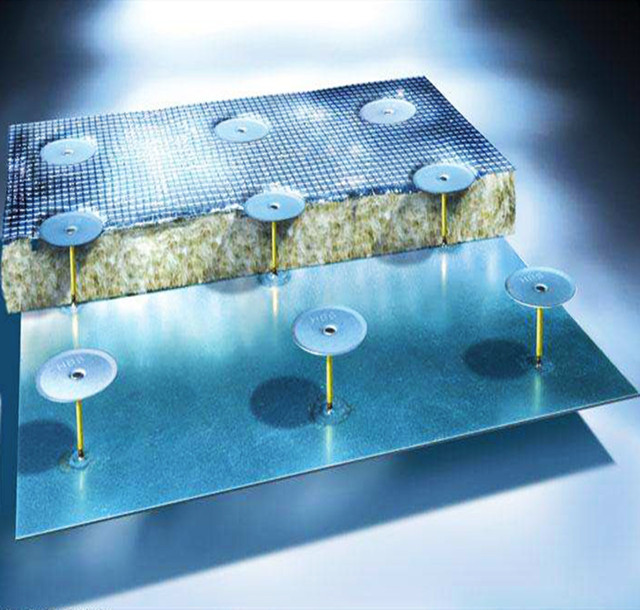

Energy storage stud welding is also known as capacitance discharge stud welding. The equipment first charges the preset amount of energy into the capacitor, and then releases all the energy from the capacitor at one time during welding. The welding time is 1-3 milliseconds.

Because the energy can not be supplied continuously, the welding capacity of stored energy stud welding is limited, and it is generally used to weld studs with a diameter of 2-10 mm.

Characteristics of stud welding with energy storage

The capacity stored energy stud welding machine is usually used to weld the studs with the diameter less than 10 mm on the thin plate (usually the plates with the diameter less than 3 mm), and the welding strength is weaker than that of the pull arc stud welding machine.

Arc stud welding is also called pull arc stud welding. Unlike energy storage stud welding, pull arc stud welding does not charge the capacitor, but directly discharges after voltage reduction through the transformer / rectifier.

Since no precharge is required, the electric energy can be continuously released, so the welding time can be controlled. According to the different power of the equipment, the diameter range of the weldable stud is 3-36mm.

Classification of arc stud welding

According to the welding time, it can be divided into long cycle arc stud welder and short cycle arc stud welder.

Long cycle arc stud welding machine, whose welding time is usually 0.5-3s, is mainly used to weld the studs with diameter M12 and above on the thick plate (usually the plate thickness is more than 3mm, and the plate thickness ≥ stud diameter × 1 / 3)

Short cycle arc stud welding machine, whose welding time is usually 0-100ms, is mainly used to weld the studs with diameter M12 and below on the thin plate (usually the plate thickness is more than 0.6mm, and the plate thickness is ≥ stud diameter × 1 / 8)

Classification of protection methods for arc stud welding machine

In order to form better solder joint and reduce oxidation, arc stud welding machine needs to provide some protection methods as much as possible. According to the protection mode, it can be divided into "no protection", "gas protection" and "porcelain ring protection".

No need for protection: usually for stud welding within M6, this process generally has no high requirements for molding aesthetics and stud strength;

Gas protection: usually a mixture of 82% argon + 18% carbon dioxide is used;

Ceramic ring protection: the way of ceramic ring protection can make the solder joint more beautiful.

Characteristics of arc stud welding machine

Due to the continuous energy input, the arc stud welding machine can weld the larger diameter studs on the thicker motherboard, and its welding strength is greater than that of the stored energy capacitor stud welding machine.

Related recommendations